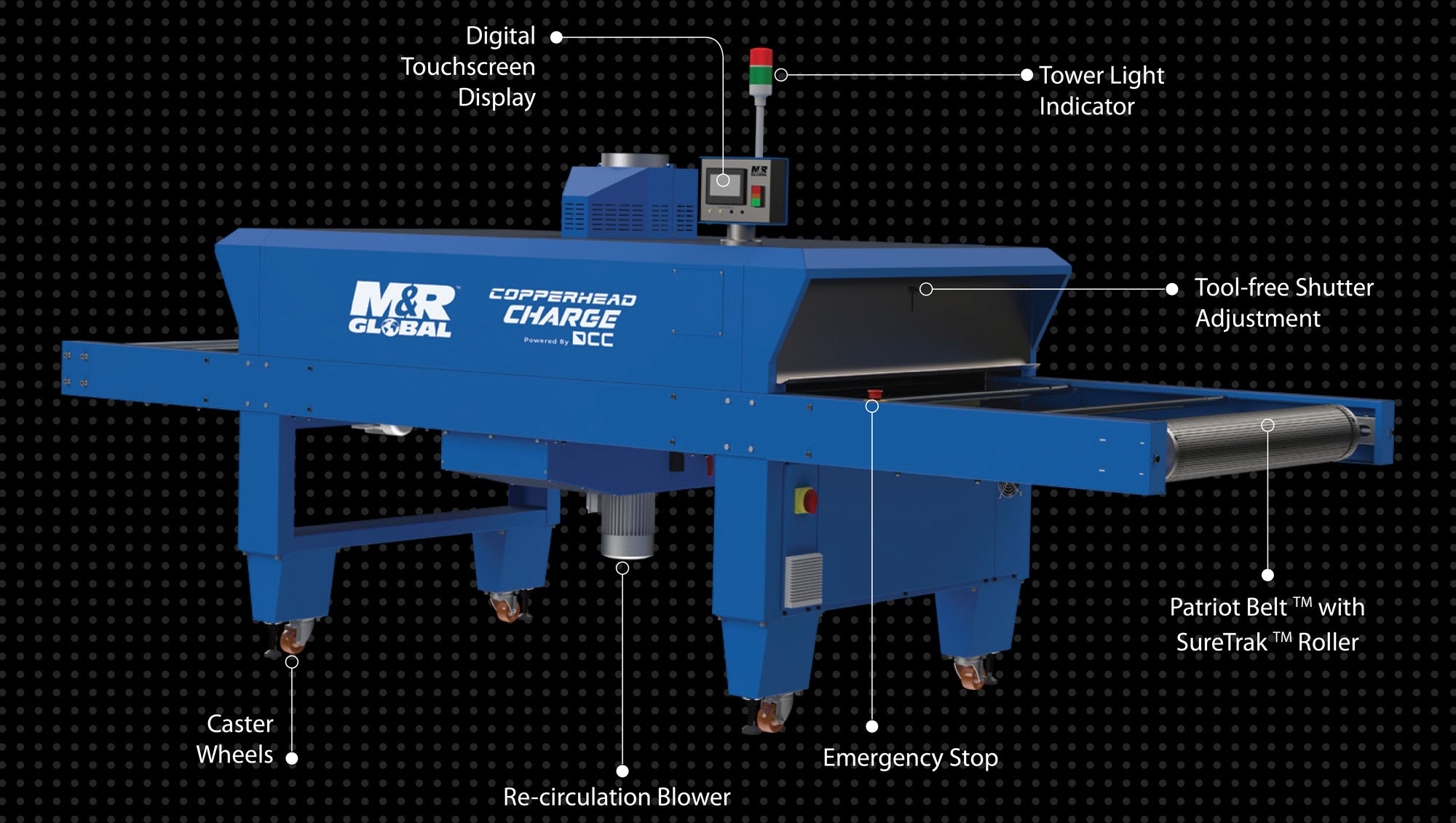

Features And Highlights

-

Heat Chamber

Infrared Radiant Panel Forced Air Curing

-

Air Handling

Up to 95% air is recirculated back in the heat chamber

-

Simplified Maintenance

Easy-to-reach filters, belt replacement and lubrication points

-

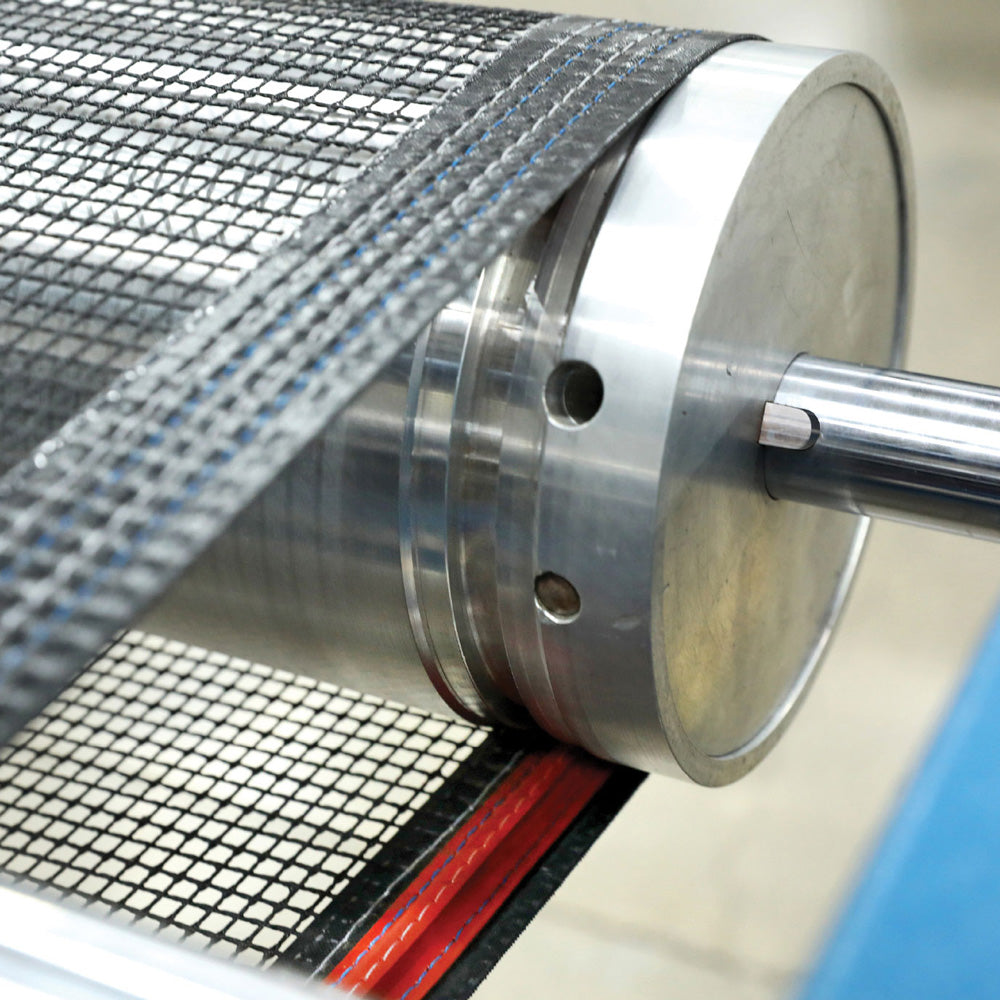

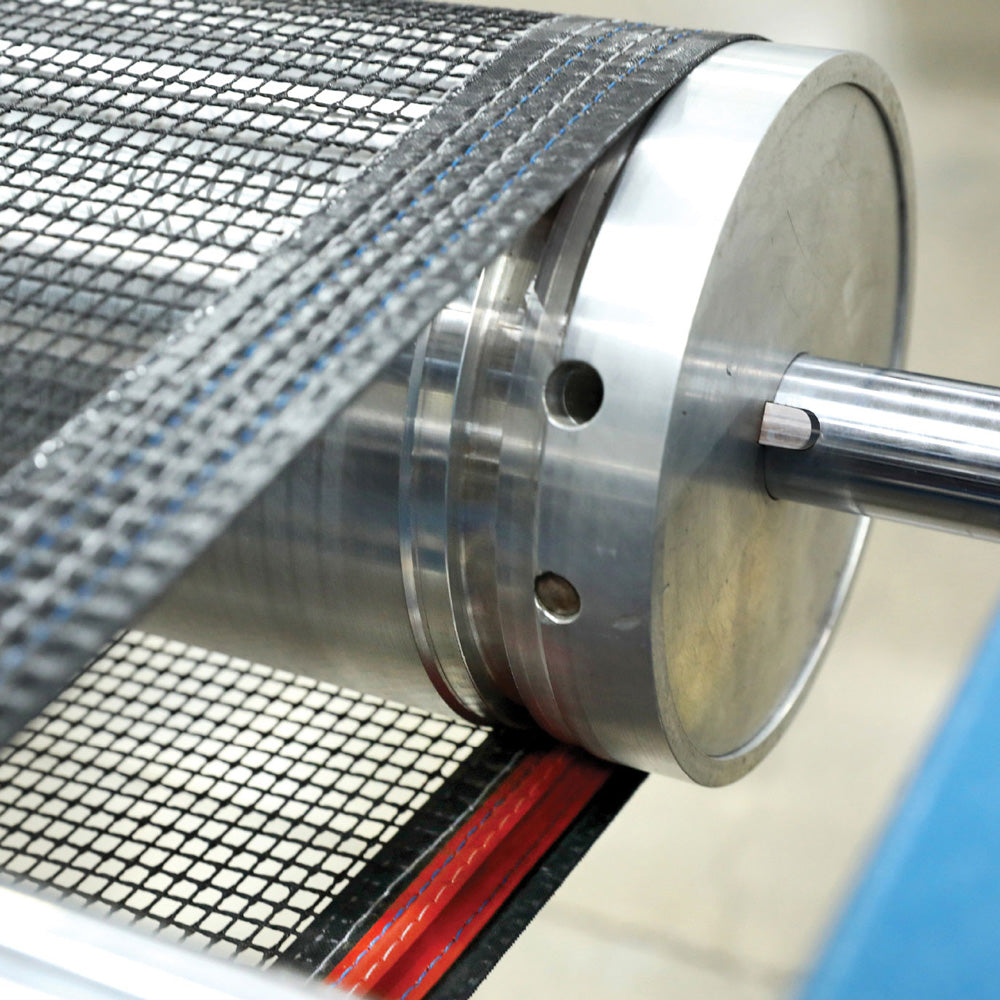

Belt Tracking System

Patriot Belt with SureTrak roller system helps to keep the belt in place

-

Control Panel

Icon-based digital touch screen control panel

-

Edge To Edge Curing

Unique Radiant Panel placement along with Air knives to ensure Edge to Edge Curing

-

Advanced Cool Skin Technology

Advanced Cool Skin Technology leaves the dryer outside surface cool to the touch

Additional Information

- HEAT CHAMBER

-

-

Curing is provided by an infrared radiant panel array and forced hot air

-

- AIR HANDLING

-

-

Two separate dedicated blowers (circulation and exhaust)

-

Up to 95% air is recirculated back in the heat chamber

-

Isolated Insulation improves curing performance by leveraging infrared energy that would otherwise be lost into the dryer's insulation

-

- INSULATION

-

- This system helps to trap the heat leakage from the heat chamber walls.

- SIMPLIFIED MAINTENANCE

-

- Nozzle Panel slides out for easy cleaning.

- BELT TRACKING SYSTEM

-

- Patriot Belt with Sure Trak roller system helps to keep the belt in place

- CONTROL PANEL

-

-

Icon-based Touch screen control Panel

-

Control Panel can be swiveled as per operator convenience

-

Digital belt speed readout makes it easy to duplicate conveyor dryer speed settings

-

Digital temperature readout shows set–point temperature and actual temperature in real time

-

Automatic Cool-Down Mode: After the dryer has been turned off, the circulation blower and conveyor belt will continue to run until the heat chamber has cooled

-

- EDGE TO EDGE CURING

-

- Unique Radiant Panel placement along with Air knives to ensure Edge to Edge Curing

- DUAL ZONE TECHNOLOGY

-

- This system helps to keep the heat chamber isolated which leaves the conveyor dryer skin cool to the touch

- OTHER FEATURES

-

-

Tool-free shutter adjustment

-

Caster wheels facilitate easy movement of the dryer

-

Can be used to cure Water-based, Discharge, Plastisol & Direct-to-Garment Prints

-

Sleek Design

-

Maintenance-free, brushless AC electric motor with variable-frequency drive provides reliable, accurate belt-speed control

-

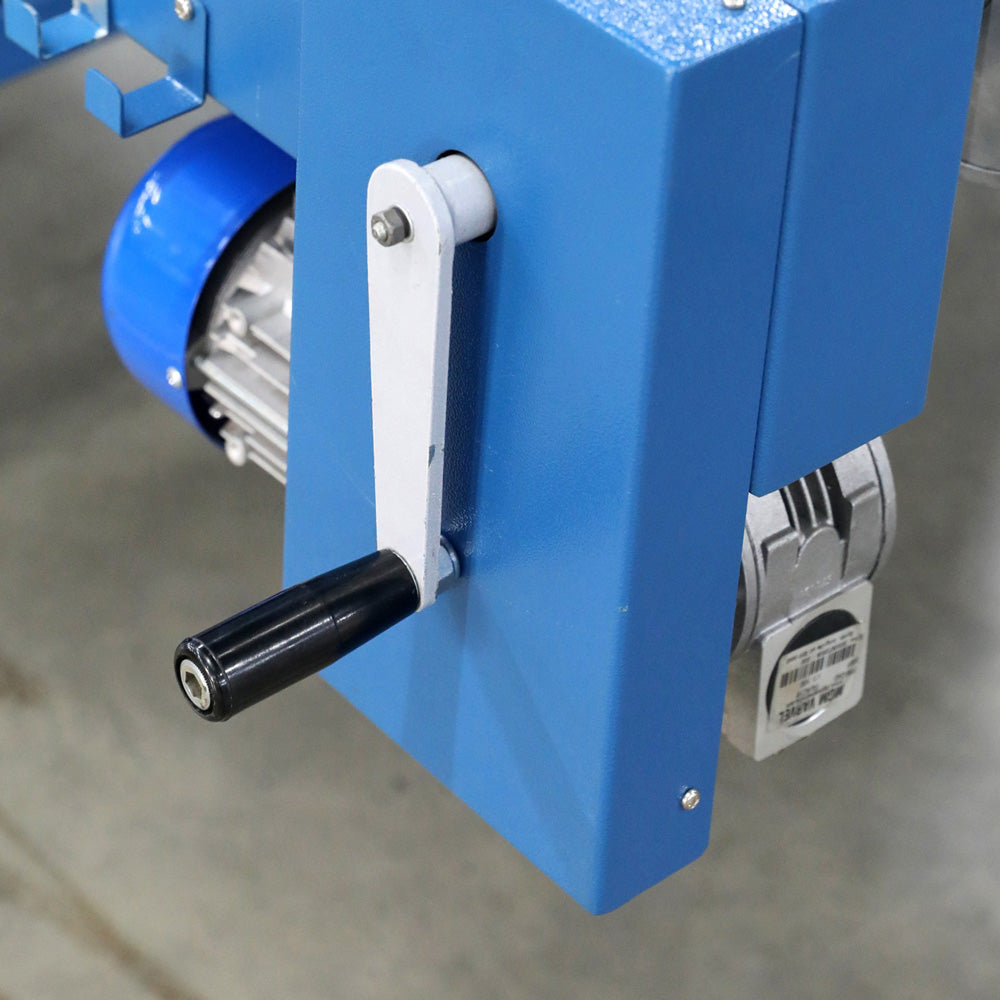

Includes a manual belt crank allowing operators to rotate the belt manually to remove shirts in-case of power outages.

-

| SPECIFICATIONS | CHARGE 24/6 |

CHARGE 24/12 |

CHARGE 36/6 |

CHARGE 36/12 |

CHARGE 48/8 |

CHARGE 48/16 |

CHARGE 60/8 |

CHARGE 60/16 |

| Belt Width | 61 cm (24") | 61 cm (24") | 91 cm (36") | 91 cm (36") | 122 cm (48") | 122 cm (48") | 152 cm (60") | 152 cm (60") |

| Electrical Requirements1 | 208-230, 1ph/3ph, 60A/48A, 50/60 Hz, 10.9 kW* (UL) 208-230, 3ph, 35A, 60 Hz, 10.9 kW (UL) 380-415 V, 3ph, 21A, 50 Hz, 10.9 kW (CE) |

208-230, 3ph, 70A, 60 Hz, 21.7 kW (UL) 380-415 V, 3ph, 42A, 50 Hz, 21.7 kW (CE) |

208-230, 1ph/3ph, 90A/70A, 60 Hz, 16.1kW* (UL) 208-230, 3ph, 51A, 60 Hz, 16.1kW (UL) 380-415 V, 3ph, 32 A, 50 Hz, 16.1 kW (CE) |

208-230, 3ph, 101A, 60 Hz, 32 kW (UL) 380-415 V, 3ph, 62 A, 50 Hz, 32 kW (CE) |

208-230, 3ph, 97A, 60 Hz, 30.7 kW (UL) 380-415 V, 3ph, 60 A, 50 Hz, 30.7 kW (CE) |

208-230, 3ph, 192A, 60 Hz, 61 kW (UL) 380-415V, 3ph, 116 A, 50 Hz, 61 kW (CE) |

208-230, 3ph, 120A, 60 Hz, 38.1 kW (UL) 380-415 V, 3ph, 72.5A, 50 Hz, 38.1 kW (CE) |

208-230, 3ph, 238A, 60 Hz, 75.7 kW (UL) 380-415 V, 3ph, 145 A, 50 Hz, 75.7 kW (CE) |

| Exhaust Blower System2,3 | 20 cm (7.9") : 8650 l/min (308 cfm) @ 1.32 mmwc (0.05"wc) |

2 nos. x 20 cm (7.9") : 8650 l/min (308 cfm) @ 1.32 mmwc (0.05"wc) |

20 cm (7.9") : 8650 l/min (308 cfm) @ 1.32 mmwc (0.05"wc) |

2 nos. x 20 cm (7.9") : 8650 l/min (308 cfm) @ 1.32 mmwc (0.05"wc) |

24 cm (9.8") : 14215 L/min (502 cfm) @ 2.0 mmwc (0.08"wc) | 2 nos. x 24 cm (9.8") : 14215 L/min (502 cfm) @ 2.0 mmwc (0.08"wc) | 24 cm (9.8") : 14215 L/min (502 cfm) @ 2.0 mmwc (0.08"wc) | 2 nos. x 24 cm (9.8") : 14215 L/min (502 cfm) @ 2.0 mmwc (0.08"wc) |

| Heat Chamber Length | 183 cm (72") | 366 cm (144") | 183 cm (72") | 366 cm (144") | 244 cm (96") | 488 cm (192") | 244 cm (96") | 488 cm (192") |

| Overal Length | 397 cm (156 ") | 580 cm (228) | 397 cm (156 ") | 580 cm (228) | 488 cm (192") | 732 cm (288") | 488 cm (192") | 732 cm (288") |

| Overal Width | 95 cm (37") | 95 cm (37") | 126 cm (50") | 126 cm (50") | 156 cm (61") | 156 cm (61") | 187 cm (74") | 187 cm (73.5") |

| Overal Height | 179 cm (71") | 179 cm (71") | 179 cm (71") | 179 cm (71") | 179 cm (71") | 179 cm (71") | 179 cm (71") | 179 cm (70.6") |

| Radiant Panel | 4 | 8 | 4 | 8 | 6 | 12 | 6 | 12 |

| Total Machine Weight | 641 kg (1413 lbs) | 991 kg (2185 lbs) | 745 kg (1642 lbs) | 1320 kg (2910 lbs) | 985 kg (2172 lbs) | 1680 kg (3704 lbs) | 1117 kg (2463 lbs) | 1908 kg (4206 lbs) |

| Standard Infeed Length | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") |

| Standard Outfeed Length | 91 cm (36") | 91 cm (36") | 91 cm (36") | 91 cm (36") | 122 cm (48") | 122 cm (48") | 122 cm (48") | 122 cm (48") |

| 1Use uninterruptible power supply (UPS) to safeguard machine from voltage fluctuation out of main supply. If incoming voltage differs from the voltage(s) listed in the brochure, calculate amperage accordingly. 2Measured at the exhaust discharge port. 3Static pressure. * The mentioned requirements are for phase convertible dryer model. |

||||||||

Is the COPPERHEAD CHARGE Electric Infrared Conveyor Dryer right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the COPPERHEAD CHARGE Electric Infrared Conveyor Dryer to your apparel decorating business.