Often Purchased With

-

RB Vibra UV DTF Ink

RB-VIBRA-UVDTF-WRegular price From $110.00 CADRegular priceUnit price per -

RB Vibra UV DTF Clear Varnish

RB-VIBRA-UVDTF-VRegular price $110.00 CADRegular priceUnit price per -

RB Vibra UV DTF Cleaning Solution

RB-VIBRA-UVDTF-CSRegular price $45.00 CADRegular priceUnit price per -

RB Vibra UV DTF Transparent Head Moisturizing Liquid

RB-VIBRA-DTF-TMLRegular price $20.00 CADRegular priceUnit price per -

RB Onyx UV DTF Film (For Roll Printing)

ONYX-UV-R24Regular price $320.00 CADRegular priceUnit price per

Features

- White Ink Automatic Circulation

Minimize clogs within the four Epson I1600 print heads and greatly extend print head lifetime. - Two Adjustable UV Lamps for Fast Curing

Adapt to different printing speeds and printing materials. - Flexi RIP Software

The printer comes equipped with Flexi RIP software which integrates image resizing, RIP functions and printing operations all together. - Superior Printing Experience

The machine is designed with openable left and right side doors, allowing you to check and do maintenance more conveniently. - Colour that Lasts

Enhance prints with long-lasting RB Vibra UV DTF ink. Pigments won't evaporate like solvents, ensuring vibrant images for years to come. Choose RB Vibra for exceptional, durable printing results. - Durability

UV inks provide higher durability and increased resistance to scratches, smudging, and other factors that can affect print quality over time, resulting in longer-lasting and vibrant images. - Versatility

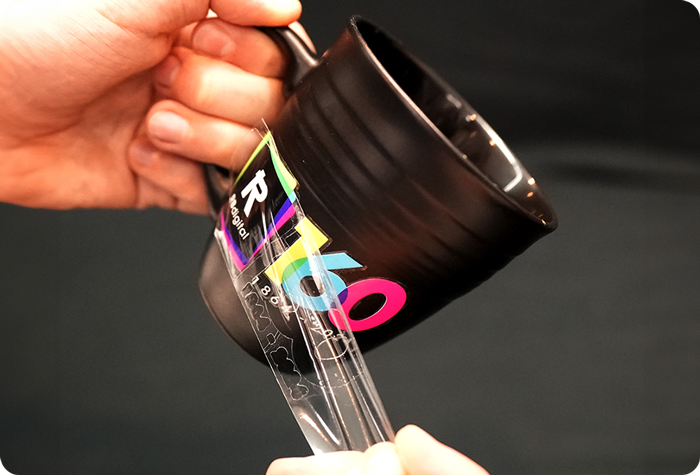

UV inks work on various surfaces including PET and polyurethane, unlike traditional inks which require absorption into substrates for printing. - No Sticky Glue Residues

No residue is left when you peel off the protective film on the A film. - More Rigid Glue Surface

Doesn’t come off when you touch the A film. - Strong Adhesion

About 1600~2000 gf / other brands average : 800~1000 gf

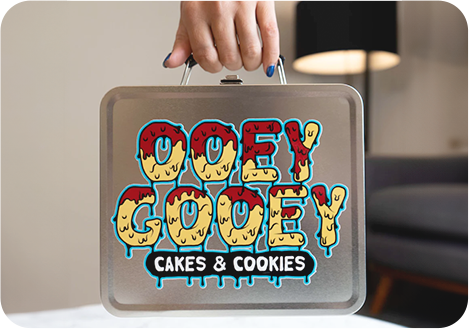

Applications

-

Plastic -

Wood -

Ceramic -

Glass -

Metal -

Leather

Additional Information

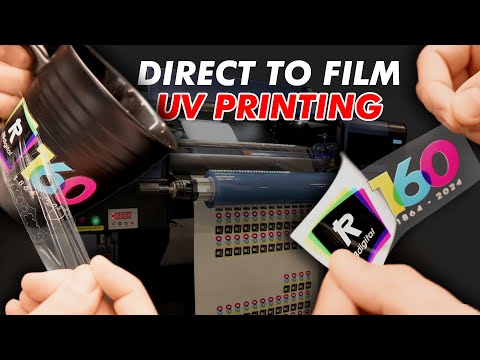

1. The design is loaded into the software, and optimized for high resolution (300 dpi or better). It includes a transparency layer to ensure seamless integration with any background and crisp edges that guarantee no blushing or blurring occurs on the edges, maintaining the design's sharpness and clarity.

2. The Rip software works seamlessly to separate colors into individual layers and channels, carefully determining the precise amount of ink to allocate to each channel of the print head. This meticulous color separation process ensures accurate color reproduction and vibrant prints that capture every detail.

3. In order to maximize the usable area of the adhesive roll for printing, the software efficiently organizes multiple designs. By strategically arranging the designs, it minimizes waste and maximizes efficiency, resulting in a more cost-effective and streamlined production process.

4. The designs are meticulously printed in layers on the adhesive "A" roll, starting with a solid white base. This base layer acts as a foundation, ensuring that the subsequent colors appear vivid and true to the original design. Each color is carefully applied, ensuring precise registration and vibrant hues. Lastly, a layer of varnish is added, providing a protective and glossy finish that enhances the overall visual appeal.

5. To ensure a secure and durable bond between the ink and adhesive, the printed stickers, decals, or logos are subjected to the power of UV lamps. These lamps emit ultraviolet light that cures the ink almost instantly, penetrating through the varnish and ink layers. This curing process creates a strong and resilient bond, ensuring that the design remains intact even under harsh conditions.

6. In the final step, the finished stickers, decals, or logos pass through an on-board laminator. This process adds an additional layer of protection and durability to the UV DTF transfers, ensuring that they are ready for application and capable of withstanding the test of time.

| Printable Width | 24" | |

|---|---|---|

| Print head | l1600 - 4 Heads | |

| Resolution | 2880DPI | |

| Speed | 8 Pass: 7m²/h, 10 Pass: 6m²/h, 12 Pass: 5m²/h | |

| Colour | CMYK + W + Varnish + Glue | |

| Print Width | 60cm | |

| Ink | RB Vibra UV DTF Ink | |

| Ink Capacity | 1.5L | |

| Operating Environment | 25°c - 30°c temperature and 50-75% humidity | |

| Power | 50HZ / 60HZ / 220V, Power 700W, 3.5A | |

| Connection | Requires an Ethernet port on connected computer. If you don't have one you will need a USB to Ethernet adapter | |

| Image Format | TIFF, JPG, Bitmap, EPS, PDF, PNG | |

| Ink Road System | Negative pressure ink bag + white ink mixing operation | |

| Machine Size | 67" x 40" x 54" (L x W x H) | |

| Packing Size | 84" x 43" x 60" (L x W x H) | |

| Doorway Clearance | Fits through 36" door frame | |

| Weight | Net Weight: 496 lbs, Gross Weight: 650 | |

Is the Toyoda Falcon UV DTF Printer right for you?

Enter your info below and a RB Digital sales representative will contact you about adding the Toyoda Falcon UV DTF Printer to your apparel decorating business.